Table of Contents

Enclosure manufacturers play a pivotal role in the safety and efficiency of electrical systems. Selecting the right manufacturer is not just about ensuring product quality but also about ensuring the longevity and reliability of the electrical components they house.

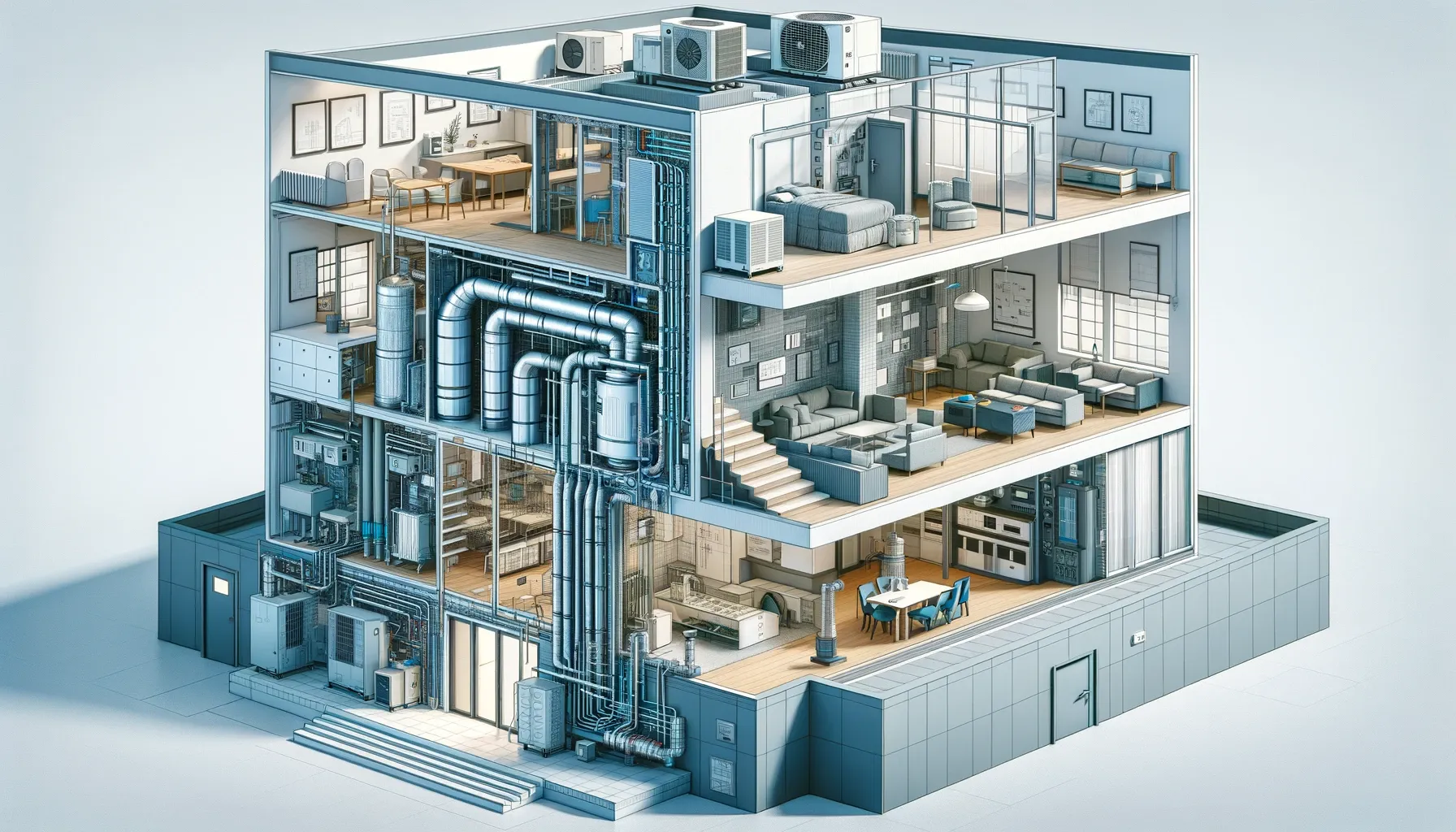

Understanding Electrical Enclosures

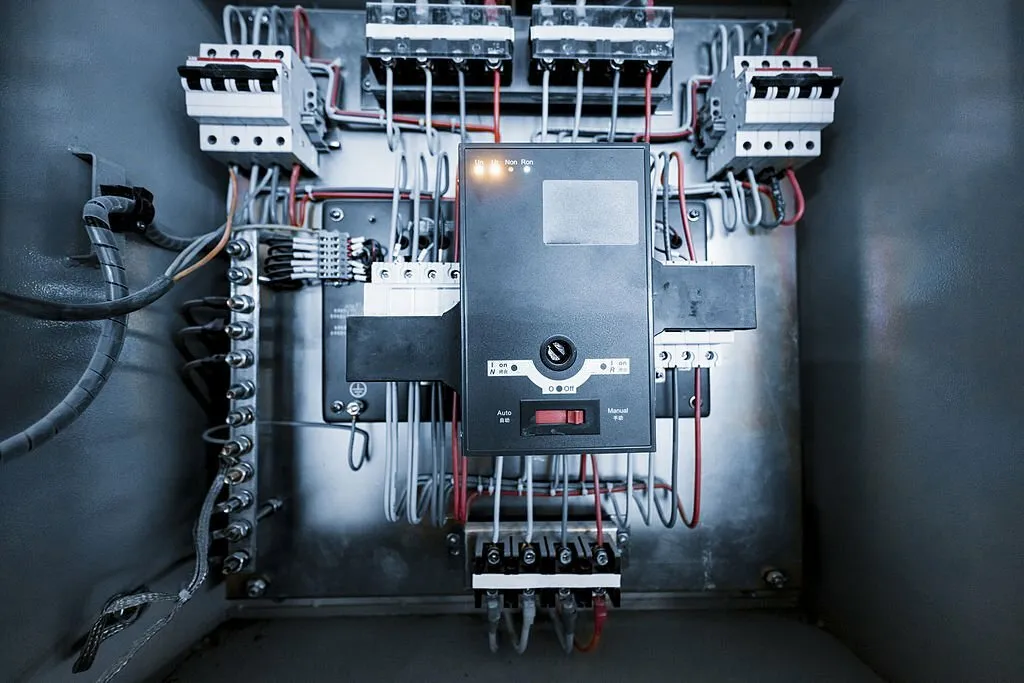

Electrical enclosures, critical for protecting sensitive electrical components, must be precision-engineered. Their quality directly impacts the safety and lifespan of the electrical equipment they house.

Key Factors in Selecting an Enclosure Manufacturer

When choosing an enclosure manufacturer, consider their adherence to industry standards like NEMA or ISO, which assure design, construction, and performance quality. Customization options are vital for specific industry needs, including modification of dimensions and special features. A range of materials like stainless steel or polycarbonate ensures suitability for various environments. Lastly, industry experience is crucial for understanding the nuances of different applications.

Leading Electrical Enclosure Manufacturers

Several top manufacturers stand out in the industry:

- Hammond Manufacturing offers a broad range of products with over 100 years of experience.

- NEMA Enclosures specializes in custom, make-to-order enclosures.

- Schaefer’s Electrical Enclosures focuses on designing custom solutions.

- Saginaw Control and Engineering is known for its steel enclosures complying with NEMA standards.

- AutomationDirect provides a wide range of NEMA electrical enclosures and industrial cabinets.

Additional Considerations

Pricing and affordability are key. Assess the balance between cost and quality, understanding that the cheapest option may not offer long-term reliability. Excellent customer support and technical assistance are essential for complex enclosure requirements.

Enclosure Standards and Certifications

Manufacturers must adhere to standards like UL, NEMA, and IEC for design and performance. Certifications from third-party labs, such as UL, assure quality and standard compliance.

Ethical and Truthful Practices in Manufacturing

Trustworthy manufacturers offer transparency and verify the accuracy of their marketing claims. Enclosures should be strong, well-sealed, insulated, aesthetically pleasing, and easy to install. Great post reading about 401(k) Withdrawal Rules.

Practical Considerations in Enclosure Selection

When selecting an enclosure, it’s important to consider various practical aspects:

Protection Rating The protection rating indicates the degree of protection against dirt and liquids. Enclosures are rated based on their ability to prevent ingress, commonly referred to as Type or NEMA ratings.

Certifications and Approvals Standards organizations like NEMA, CSA, UL, and IEC define categories for enclosures. These ratings guide users in choosing products that offer the right level of protection.

Size Consider the minimum dimensions needed to house all installed components and the physical size limitations of the installation area. Hammond offers over 600 sizes of standard enclosures to meet various application sizes.

Access Enclosure access is typically through a front door/cover, with options like latches, clamps, handles, or screws. Large enclosures may offer rear doors or removable side panels. Security considerations can include padlock hasps, tamper-proof screws, or key-lockable hardware.

Cost To save costs, don’t over-specify the protection level. For instance, a clean commercial environment usually only needs a Type 1 level of protection. Custom designs typically drive costs up, so using standard or modified standard enclosures is more economical.

Temperature Environment Consider the ambient temperature where the enclosure will be installed, as it impacts equipment performance. In warm environments, larger enclosures or supplementary cooling apparatus may be necessary. In colder climates, heating solutions might be needed.

Corrosion Resistance The choice of materials (like Stainless Steel, Aluminum, and Polycarbonate) depends on the corrosiveness of the environment. Type 4X standard is known for corrosion resistance, but its effectiveness varies based on specific environmental factors.

FAQs

Q: Who are the top electrical enclosure manufacturers?

Q: What services do precision sheet metal fabrication companies offer?

Q: How can I choose the right electrical enclosure manufacturer?

Q: What makes precision sheet metal fabrication accurate?

Q: How long does it take to manufacture an electrical enclosure?

Final Recommendations

Selecting the right enclosure manufacturer involves a careful evaluation of protection ratings, standards and certifications, size requirements, access needs, cost considerations, temperature environment, and corrosion resistance. By considering these factors, you can choose a manufacturer that best suits your specific needs, ensuring the safety, efficiency, and longevity of your electrical equipment.